Mechanical engineering is one of the strongest pillars of modern industrial growth. From manufacturing and automotive to energy systems and automation, the field influences nearly every aspect of industrial progress. At JD Engineering, we deliver professional mechanical engineering services that support industries in building efficient systems, improving productivity, and driving innovation.

Mechanical engineering has shaped industrial society for centuries, but in today’s advanced era powered by automation, robotics, and smart manufacturing the role of this discipline is more essential than ever. In this article, we break down the importance, impact, responsibilities, and future of mechanical engineering in the industrial world.

The Foundation of Mechanical Engineering in Industry

Mechanical engineering is the branch of engineering that designs, analyzes, and builds machines, systems, and devices used across industrial sectors. It combines scientific principles, mathematics, materials science, and technology to create solutions that keep industries functioning smoothly.

Industrial society relies heavily on machines. These machines, in turn, rely on the expertise of mechanical engineers. Whether it’s designing a manufacturing plant layout, optimizing HVAC systems, automating production lines, or developing heavy machinery, mechanical engineering strengthens the backbone of industrial operations.

With evolving technology, industries are now demanding more efficient, sustainable, and innovative engineering solutions. This is why professional mechanical engineering consulting has become essential for businesses seeking cost-efficiency and competitive advantage.

Importance of Mechanical Engineering Services in Industrial Development

The growth of any industrial society depends on its ability to produce goods efficiently, sustainably, and safely. This is where mechanical engineering services become essential.

Mechanical engineering supports industrial development by:

- Enhancing production speed and consistency

- Improving energy efficiency across operations

- Designing systems that increase automation and reduce human error

- Ensuring safety standards and compliance with industrial regulations

- Reducing operational and maintenance costs

- Supporting innovation with advanced mechanical engineering designing

Modern industries cannot operate without robust mechanical systems. Whether it’s a small manufacturing unit or a large-scale industrial plant, mechanical engineering plays a vital role in ensuring seamless operations.

Mechanical Engineering and the Evolution of Industrial Technology

Industrial technology has evolved rapidly, and mechanical engineering has been at the heart of this evolution. The Industrial Revolution introduced early mechanical machines such as steam engines and spinning machines. Today’s world uses advanced robotics, 3D printing, CAD/CAM systems, and industrial automation all developed or optimized by mechanical engineers.

Key areas where mechanical engineering supports technological advancements include:

- Automation and robotics engineering

- Computer-aided designing (CAD)

- Artificial Intelligence in manufacturing

- Smart factories and IoT-enabled machinery

- Energy-efficient HVAC systems

- Advanced material selection for industrial machines

Mechanical engineering consulting helps industries adopt the latest technologies without operational disruptions.

Role of Mechanical Engineers in Modern Industrial Society

Mechanical engineers are problem solvers, innovators, and system designers. Their expertise ensures industrial operations run smoothly, safely, and economically.

The roles of mechanical engineers include:

- Designing industrial equipment and machinery

- Conducting maintenance and performance analysis

- Improving production processes

- Building prototypes and conducting product testing

- Enhancing energy efficiency in manufacturing systems

- Supervising mechanical and engineering services operations

- Ensuring safety and reliability in industrial systems

- Integrating automation technologies into production lines

Their work directly influences the productivity, output, and sustainability of industries.

Mechanical Engineering Designing | A Core Component of Industrial Efficiency

Mechanical engineering designing is the foundation of every industrial machine and operational system. Without effective design planning, industries would suffer breakdowns, inefficiencies, and costly downtime.

Key elements of mechanical engineering designing:

- 3D modeling and simulation

- Stress, load, and thermal analysis

- System optimization

- Prototype development

- Material selection and performance testing

- Life cycle assessment and cost analysis

Advanced design tools such as SolidWorks, AutoCAD, Ansys, and CATIA help engineers create efficient, durable, and optimized systems.

Industrial Applications of Mechanical Engineering

Mechanical engineering is used across nearly every industrial domain. Its applications are diverse, wide-ranging, and crucial for both production and innovation.

Major industrial applications include:

1. Manufacturing Industry

- Assembly line automation

- CNC machines and robotics

- Product design and optimization

- Tooling and fixture development

2. Automotive Industry

- Vehicle design and testing

- Engine development

- Thermal management systems

- Safety and crash simulation

3. Power & Energy Sector

- Renewable energy systems

- Power plant machinery

- Turbines, boilers, and heat exchangers

- Energy efficiency optimization

4. Construction & Infrastructure

- HVAC designing

- Material handling systems

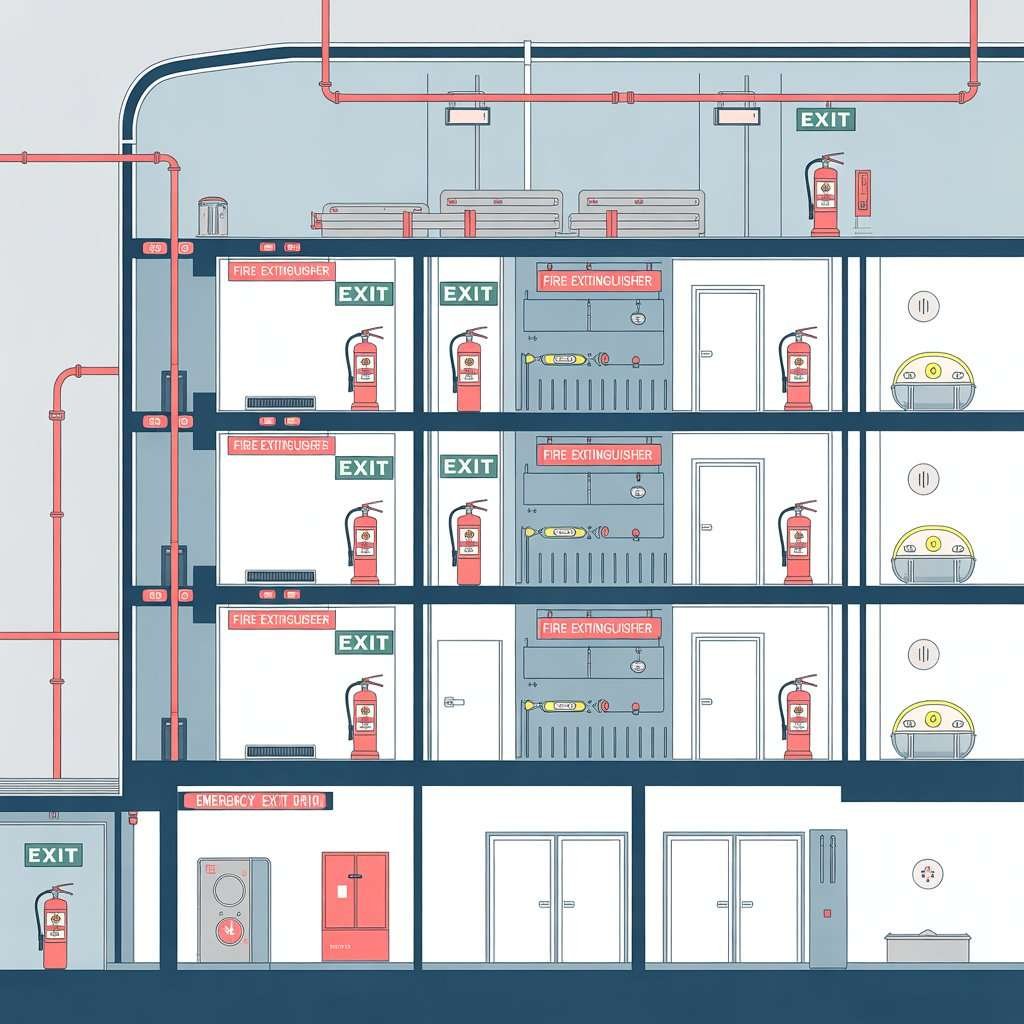

- Water pumping and fire safety mechanisms

- Industrial building mechanical layouts

5. Oil & Gas Industry

- Pipeline engineering

- Pressure vessel designing

- Offshore mechanical systems

- Refinery machinery

6. Food & Beverage Industry

- Industrial refrigeration

- Food processing machines

- Packaging automation

Every industrial sector depends on efficient machines and every machine depends on mechanical engineers.

Mechanical Engineering Services Company | Why Businesses Need One

Partnering with a professional mechanical engineering services company gives industries access to expertise, tools, and technologies they cannot maintain in-house.

Benefits of hiring mechanical engineering services:

- Reduced operational costs

- Faster project execution

- Accurate technical documentation

- Higher equipment efficiency

- Improved safety and compliance

- Access to advanced engineering tools

- Expert troubleshooting and maintenance

Mechanical engineering consulting helps industries solve complex technical challenges while staying aligned with global standards.

The Role of Mechanical Engineers in Industrial Safety and Compliance

Industrial operations involve heavy machinery, high temperatures, pressure systems, and hazardous materials. Mechanical engineers ensure that these operations meet safety regulations and function without risks.

Safety roles include:

- Risk assessment & hazard analysis

- Equipment failure prediction

- Compliance with ASME, ISO, OSHA, and local regulations

- Designing safe operating procedures

- Implementing preventive maintenance schedules

Industries heavily depend on mechanical experts to prevent accidents, reduce workplace injuries, and maintain workflow continuity.

The Future of Mechanical Engineering in Industrial Society

The future of industrial society is driven by automation, sustainability, and AI-enabled systems. Mechanical engineering will play an even more critical role in shaping this future.

Future trends:

- Smart factories powered by AI & IoT

- Autonomous vehicles

- Advanced robotics

- 3D printing in manufacturing

- Renewable energy systems

- Green engineering and sustainability

- Hyper-efficient mechanical engineering designing

As industries become more digital, mechanical engineering services will become essential for integrating intelligent technologies.

Frequently Asked Questions (FAQ)

1. What is the main role of a Mechanical Engineer?

The main role of a mechanical engineer is to design, build, analyze, and improve mechanical systems used in industries. They focus on making machines efficient, safe, and reliable while supporting manufacturing, energy, transportation, and construction sectors.

2. What does an industrial Mechanical Engineer do?

An industrial mechanical engineer works on machinery, automation, production systems, and industrial operations. Their tasks include equipment design, maintenance planning, performance optimization, safety analysis, and integrating modern technologies like robotics and IoT into manufacturing processes.

3. Why do you think mechanical engineers are important in society?

Mechanical engineers are essential because they develop the machines, tools, and systems that power daily life and industrial growth. They enable innovation, improve safety, support economic development, and contribute to creating sustainable and efficient industrial systems.

Conclusion

Mechanical engineering plays a central and irreplaceable role in shaping industrial society. It drives innovation, strengthens manufacturing capabilities, improves energy efficiency, and ensures the safe and reliable functioning of countless industrial systems. From designing advanced machinery to optimizing production lines, mechanical engineering services empower industries to operate smarter, faster, and more sustainably.