Quality assurance plays a foundational role in the success of all engineering disciplines. For modern electrical engineering companies, quality assurance (QA) ensures safety, performance, and reliability in every project. It builds trust with clients, strengthens brand authority, and prevents costly failures that can harm both people and infrastructure.

In today’s competitive landscape, QA is no longer optional. Whether the work involves electrical engineering services, structural design, engineering electronics, or complex systems involving an electrical mechanical engineer, quality assurance acts as the backbone of the engineering lifecycle.

This blog explores why QA is essential, how it is applied across engineering industries, and why organizations that prioritise QA outperform others.

What Is Quality Assurance in Engineering?

Quality assurance in engineering refers to a structured process that ensures products, designs, systems, and services meet predefined quality standards. These standards are based on safety regulations, project requirements, engineering codes, and industry best practices.

QA is a proactive approach. It focuses on preventing errors, improving workflows, and ensuring that every engineering output is safe, efficient, and robust.

Unlike quality control (QC), which checks for defects after production, QA aims to eliminate problems long before they occur. This approach reduces cost, enhances durability, and improves satisfaction for clients working with electrical engineering companies or multi-discipline firms.

Why Quality Assurance Is Important for Electrical Engineering Companies

For electrical engineering companies, a single design flaw can cause equipment damage, system outages, or safety hazards. Quality assurance helps prevent engineering errors while protecting assets, people, and businesses.

Key advantages include:

- Better safety compliance in line with national and international electrical standards

- Improved project reliability especially in power distribution, automation, and control systems

- Reduced risk of failures in electrical installations, cables, control panels, and substations

- Higher client trust and reputation in the engineering marketplace

- Cost savings through early-stage risk mitigation

Whether delivering turnkey projects, industrial systems, building automation, or electrical engineering services, QA ensures consistent and flawless performance.

Benefits of Quality Assurance for Engineering Electronics and Mechanical Systems

Engineering projects often involve multidisciplinary teams. For example, an electrical mechanical engineer collaborates across departments to deliver integrated systems. Quality assurance brings alignment and clarity to these collaborative workflows.

Major benefits include:

- Enhanced cross-functional coordination

- Reduced design clashes between electrical, mechanical, and electronics systems

- Higher product lifespan due to better design validation

- Improved energy efficiency and sustainability

- Better documentation and traceability

In fields like engineering electronics, QA is even more critical because device performance relies on precision, reliability, and zero tolerance for errors.

Top Reasons Why Quality Assurance Is Important in Engineering

Quality assurance influences every engineering activity from conceptual design to installation, testing, and commissioning.

Below are the key reasons why QA is essential.

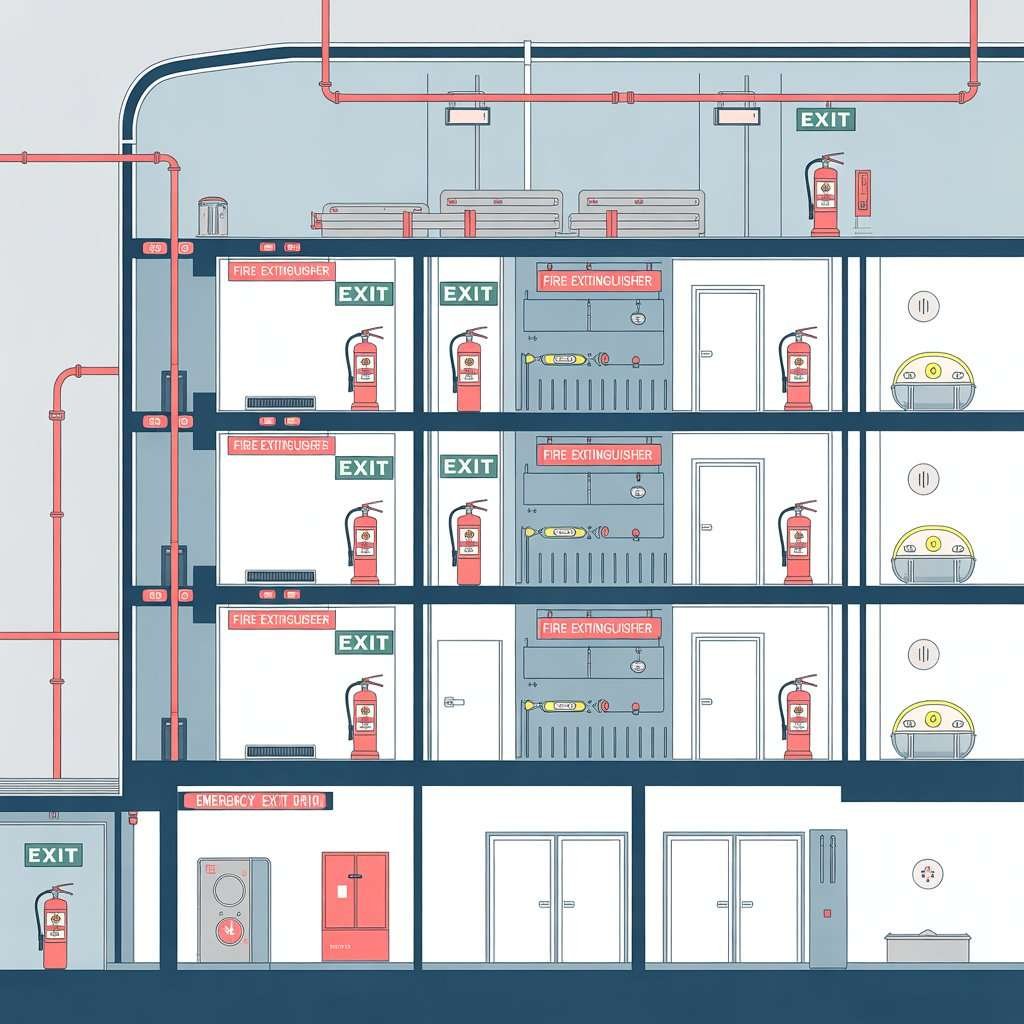

1. Ensures Safety and Compliance

Engineering always involves risk. Whether you’re working in electrical, electronics, mechanical, or civil domains, safety is the priority.

Quality assurance ensures:

- Compliance with IEEE, IEC, NEC, IS, and industry codes

- Safe electrical load distribution

- Proper grounding, insulation, and protection systems

- Documented safety protocols and approval processes

For electrical engineering companies, this is especially important because safety failures can lead to fires, electric shocks, or large financial losses.

2. Reduces Engineering Risks and Project Failures

Errors in engineering systems may not appear during installation but could surface during operation. QA prevents such hidden risks.

QA ensures:

- Early detection of design flaws

- Effective risk assessment

- Regular testing and performance evaluation

- Structural and electrical resilience

Risk mitigation saves time, resources, and reputational value.

3. Enhances System Reliability and Lifetime Performance

Every client expects long-lasting, trouble-free engineering systems. Quality assurance ensures optimal performance from day one.

Engineering reliability improves through:

- Design audits

- Material quality verification

- Performance testing

- Periodic inspections

This is crucial for engineering electronics, automation systems, and high-value industrial machinery.

4. Saves Cost Through Prevention, Not Repairs

Correcting a design flaw early costs far less than fixing a problem after installation.

For instance:

- Replacing faulty wiring in a commercial building

- Modifying control panels after commissioning

- Rectifying a mismatch between electrical and mechanical loads

Quality assurance reduces these expenses by ensuring accuracy at each step.

Builds Customer Trust and Industry Reputation

Clients prefer working with electrical engineering companies that demonstrate professionalism and deliver consistent quality.

QA demonstrates:

- Reliability

- Transparency

- Technical competence

- Commitment to long-term performance

This increases repeat business and helps companies win large turnkey projects.

What Does a Quality Assurance Engineer Do?

A Quality Assurance Engineer plays a strategic role in the engineering lifecycle.

Key Responsibilities:

- Develop and implement QA frameworks

- Conduct design and document audits

- Identify risks and propose corrective actions

- Perform inspections and verify compliance

- Manage testing, validation, and certification processes

- Coordinate with electrical, mechanical, and electronics teams

- Maintain industry-standard documentation

QA engineers ensure that all deliverables from electrical drawings to mechanical equipment meet strict quality benchmarks.

The 5 Pillars of Quality Assurance in Engineering

Quality assurance follows universal principles. These pillars guide engineering firms toward delivering exceptional results.

1. Customer Focus

Understanding client requirements and translating them into engineering designs.

2. Process Approach

Working with structured workflows to minimize errors.

3. Continuous Improvement

Constantly enhancing methods, tools, and skills.

4. Evidence-Based Decision Making

Using data, testing, and analysis for accuracy.

5. Leadership Commitment

Management plays a key role in enforcing quality standards.

These five pillars ensure excellence in all engineering disciplines from engineering electronics to large-scale electrical infrastructure.

Stages of QA Implementation in Engineering Projects

1. Planning

Identify requirements, risks, and standards.

2. Design Review

Ensure drawings, models, and calculations meet quality benchmarks.

3. Testing & Validation

Evaluate performance under various conditions.

4. Implementation & Installation Checks

Ensure installations follow code-compliant procedures.

5. Final Inspection & Handover

Verify all parameters before client approval.

Frequently Asked Questions

1. What is quality assurance and why is it important?

Quality assurance is the process of ensuring engineering systems meet safety, performance, and compliance standards. It prevents errors, reduces risks, and ensures long-term reliability of engineering solutions.

2. What is the role of a quality assurance engineer?

A QA engineer develops and manages quality frameworks, performs audits, conducts inspections, ensures compliance, and collaborates with electrical, mechanical, and electronics teams to ensure flawless project execution.

3. What are the 5 pillars of quality assurance?

The five pillars are:

- Customer Focus

- Process Approach

- Continuous Improvement

- Evidence-Based Decision Making

- Leadership Commitment

Conclusion:

Quality assurance drives engineering excellence. It protects people, improves reliability, reduces cost, and strengthens trust. For electrical engineering companies and multidisciplinary firms, QA is the foundation that ensures long-term success.

If your engineering projects aim for precision, safety, and world-class standards, prioritizing QA is non-negotiable.